Everything That Rotates Needs To Be Balanced

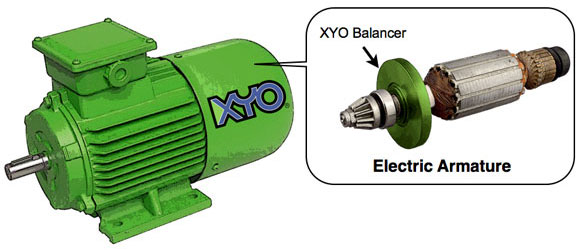

The XYO Balancing Technology delivers energy efficient, high performance solutions for rotating equipment, machinery and devices

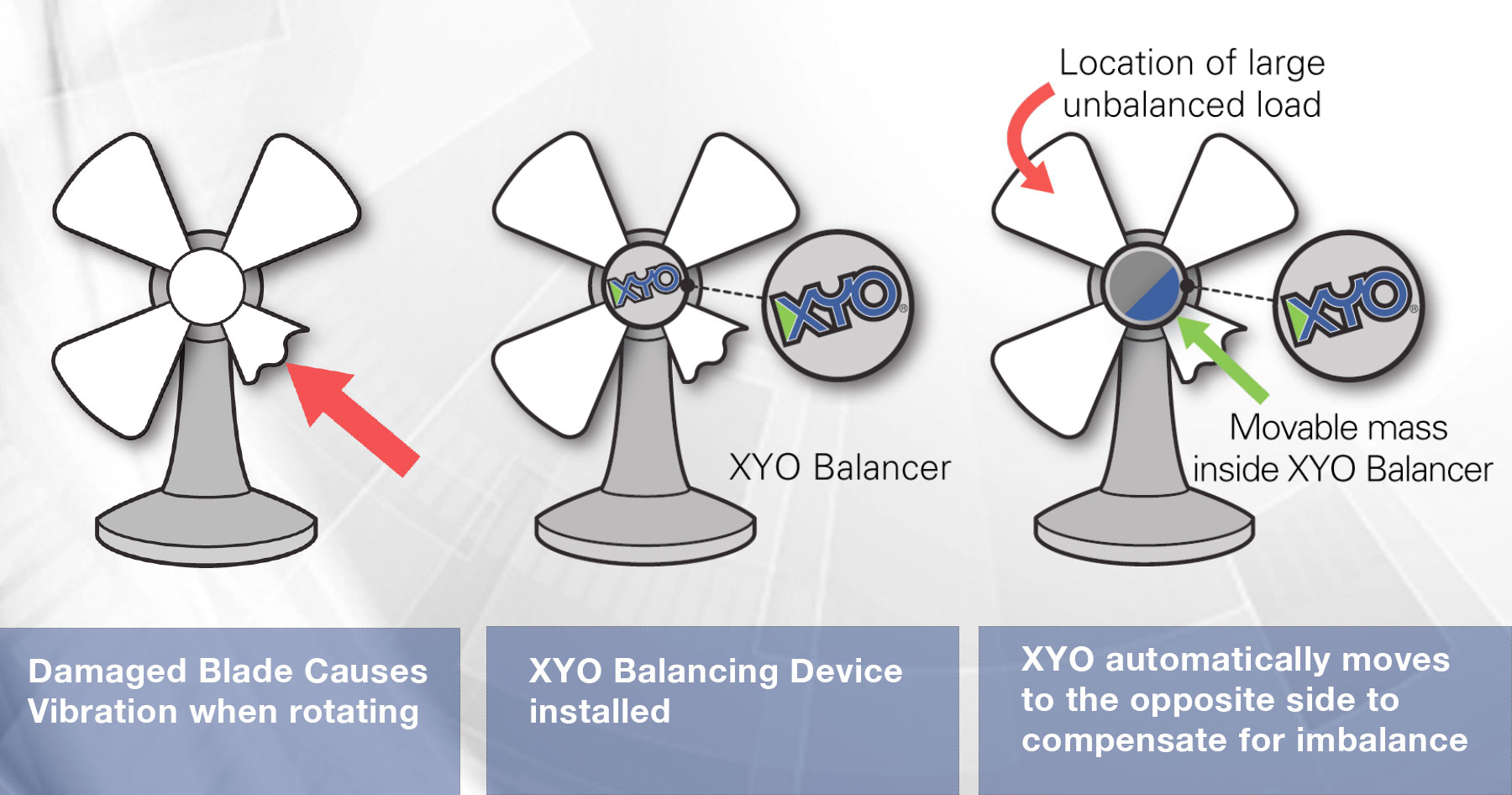

Automatic Balancing

The XYO technology harnesses rotor displacement energy to move compensating masses and automatically corrects for the imbalance and reduces vibration.

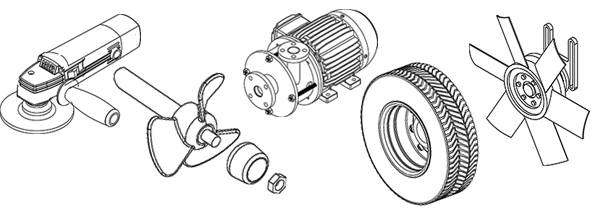

- XYO can be customized for virtually everything that rotates, creating an unlimited market potential

- The XYO Mechanical Balancing Technology is a proprietary design.

- Optimized specifically to eliminate vibration in rotating equipment and allow environmentally responsible products to operate more efficiently.

The XYO Balancer Advantages

Significantly decreases vibration and power consumption

Reduces mechanical wear, tear and maintenance costs

Lowers noise emmissions and optimizes operational efficiency

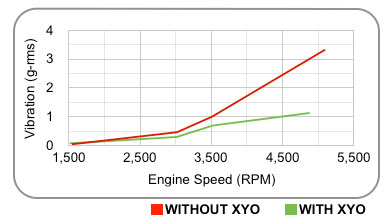

With and Without XYO

Video Demo

- Perpetual's proprietary technology is known as The XYO Mechanical Balancing Technology.

- We are world experts in vibration reduction and development of innovative, energy efficient products using The XYO Balancing Technology

How XYO Technology Works

XYO harnesses rotor displacement energy to move compensating masses within components of the system, which corrects for the imbalance of the rotor and substantially reduces vibration.

Award Winning Technology

German Engineering Award

Gold Medal

The International Exhibition of Inventions Geneva, Switzerland

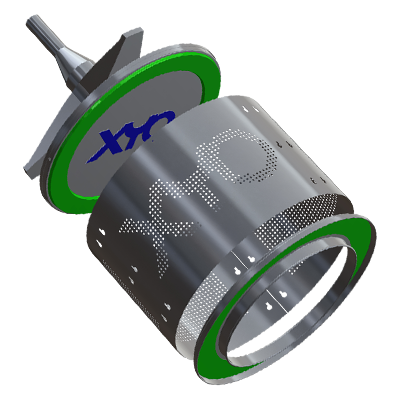

Examples of Custom Designed XYO Balancers

- Our expertise associated with the XYO technology is a result of over 25 years of research & development.

- The XYO Technology is unlimited and can be customized for virtually everything that rotates.

- The XYO Balancer can be an important value-added technology for creating energy efficient products.

The Reduction of Vibration When Using XYO Technology

| Automotive Driveshaft | 91% |

| Washing Machines | 89% |

| Refrigeration Compressors | 85% |

| Industrial Fans | 83% |

| Engine Fan | 80% |

| Professional Angle Grinders | 63% |

| Boat Propellers | 47% |

| Electric Trolling Motors | 41% |

XYO Applications and Market Potential

| AUTOMOTIVE | WHITE GOODS | HVAC | UTILITY | CENTRIFUGE | VEHICLES | AIRCRAFT |

| IC Engines | Washing Machines | Fans | Generators | Medical | Automobiles | Turbines |

| Wheels | Blenders & Processors | Blowers | Power Hand Tools | Mining | Motorcycles | Propellers |

| Cooling & Heating | Vacuums | Air Conditioning | Mowers | Industrial Processing | Watercraft | Drones |

Products Tested with XYO Technology

- Washing Machines

- Angle Grinders

- Propellers

- Trolling Motors

- Automomotive

- Engine Fans

- Compressors

- Pumps

- Electric Motors

Impact of XYO on Washing Machines

- Vibration reduced by 89%

- Spin speed increased by 29 RPM

- Power consumption decreased 43%

- Noise levels decreased 11.3dB

- Greater water extraction

- Reduce/eliminate counterweights

- Lowers shipping & transport costs

- Decreased mechanical wear

- Improved longevity and lower warranty repair costs

Spin Basket with XYO Balancers

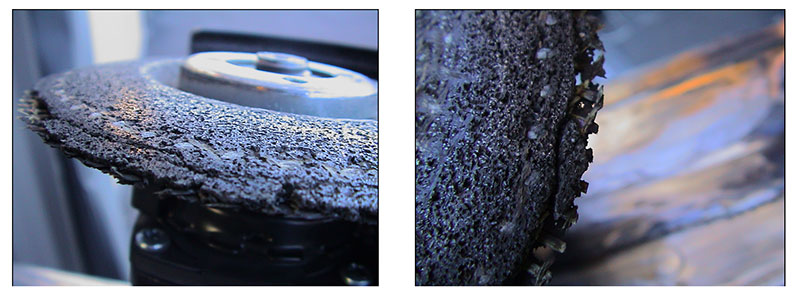

Impact of XYO on Angle Grinders

- Vibration reduced by 63%

- Low risk of developing vibration-related illnesses

- Greater productivity

- Increased product life

- Minimized employer liability

Mass Imbalance of Grinding Disks

The XYO balancer will compensate for dynamic or static unbalanced forces during an angle grinder's operation. As a result, the balancer-equipped angle grinder will continue to provide consistent performance even when the mass imbalance varies due to wear of the grinding disc that is associated with typical use.

White Finger Caused by Vibration in Hand Tools

Power tools have been known to induce the risk of vibration-related diseases. An acute disease that is caused by regular exposure to Hand-arm vibration (HAV) is known as white finger or Raynaud’s disease. Implementing XYO in Angle Grinders could significantly lower the risk of professional workers developing vibration related illnesses such as White Finger Disease.

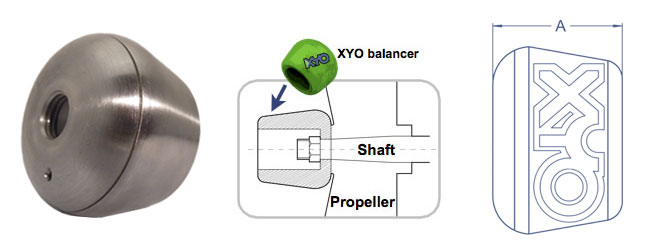

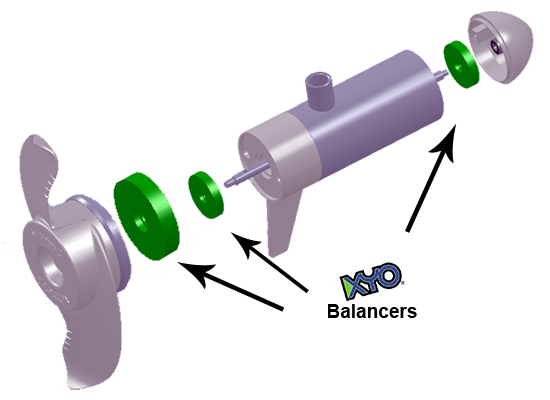

Impact of XYO on Boat Propellers

- Propeller balancing & rebalancing costs are unnecessary

- Balances propeller to a higher tolerance and is significantly better than costly conventional balancing methods

- Decreased mechanical wear of drivetrain components

- Reduced drivetrain maintenance costs

- Improved power and fuel efficiency

- Propeller runs smoothly, even with minor damage

Propeller Balancing & Maintenance

Boat propellers have to be properly maintained in order to maximize their performance. Propeller balancing is an important step to ensure that vibration levels are kept to a minimum. Expensive custom balancing using conventional balancing techniques is necessary if you want to lower propeller vibration. Boat owners are faced with high rebalancing, maintenance and repair costs, making it expensive to own and properly maintain a boat.

Integrating The XYO Balancing Technology into a Boat Prop will result in lower propeller vibration and minimal operational costs. The product is designed to automatically and continuously keep the propeller in perfect balance, thereby delivering improved performance and efficiency.

Propeller Vibration Reduced by up to 66%

Impact of XYO on Trolling Motors

- Vibration reduced by 47%

- Energy usage decreased by 20%

- Batteries can run for longer periods due to reduced energy usage

- Minimize mechanical wear and longer product life

- Lower maintenance & repair costs

- Propeller runs smoothly even with minor damage

- Lower manufacturing costs by eliminating conventional balancing methods

Market Potential

XYO has huge potential in marine applications. By optimizing and implementing the XYO Balancing Technology into boat trolling motors, Perpetual can provide a strong competitive advantage in the billion dollar marine marketplace. Both manufacturers and aftermarket consumers can benefit by reducing time and energy balancing their propellers, while gaining a superior ride quality, improved fuel consumption, reduced vibration, and protection against severe propeller damage.

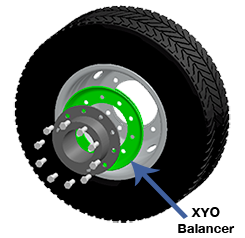

Truck Wheels

Wheels require conventional balancing during installation as well as costly periodic balancing which increase overall maintenance costs. XYO can vastly improve wheel balancing to reduce vibration, increase tire life, improve handling, and increase fuel efficiency.

Impact of XYO on Truck Wheels

- Automatic and continuous balancing of the wheel.

- Reduced vibration and wear of the tire and other components.

- Improved driver comfort.

- Improved handling and safety of driver and cargo.

- Reduced fuel consumption.

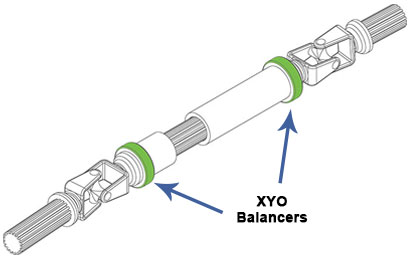

Drive Shafts

Drive shafts have to be balanced to run efficiently and ver time, corrosion and damage leads to increasing imbalance and vibration.

XYO can significantly reduce vibration for increased efficiency and less mechanical wear and tear.

Impact of XYO on Drive Shafts

- Vibration decreased 91%

- Lower manufacturing costs

- Reduced mechanical wear

- Increased power transmission

- Decreased fuel consumption

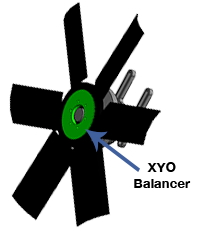

Clutch Fans

Clutch fans draw significant power from the engine to operate causing increasing fuel costs. Dust can build up on blades which causes imbalance and vibration that eventually leads to overheating. XYO can automatically compensate for this imbalance for increased fuel efficiency and less maintenance.

Impact of XYO on Clutch Fans

- Vibration lowered by 80%

- Mass imbalances is automatically and dynamically corrected.

- Current static balancing processes can be eliminated.

- Less power and fuel are needed to run the fan

- Engine efficiency is increased.

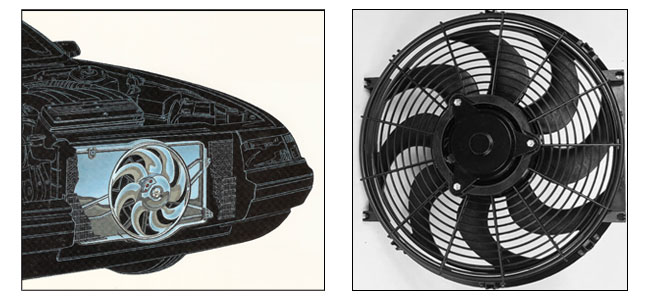

Impact of XYO on Engine Cooling Fans

- Reduced vibration by 80%

- Lower manufacturing costs

- Quieter Operation

- Decreased power consumption

- Increased product efficiency

Engine Cooling Fans Application of XYO Technology

An engine cooling fan is used to cool down a radiator. The primary cause of vibration problems in engine cooling fans is mass imbalance due to manufacturing tolerances, defects, etc. Additional mass imbalance is also accumulated over time during operation. The XYO balancer will compensate for initial imbalance originating from differences in mass distribution at different speeds.

The XYO technology reduces vibration by compensating for variable mass imbalance during the operation of engine fans. Tests show that the a prototype XYO balancer had a significant impact on reducing vibration levels of these fans.

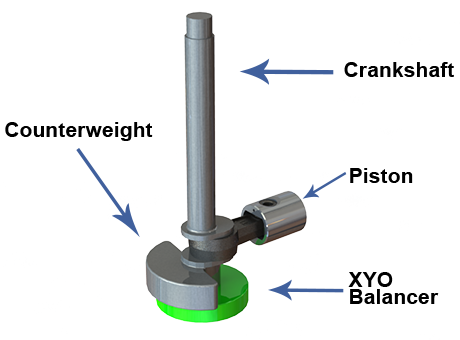

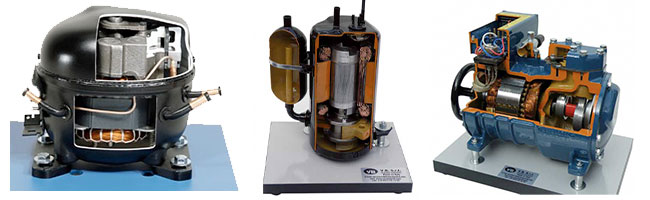

Impact of XYO on Compressors

- Reduces vibration by up to 85%

- Increases energy efficiency up to 25%

- Minimizes mechanical wear.

- Decreases noise levels

- Lowers operating costs

Compressor models that could benefit from the XYO Technology

Reciprocating Compressors are a prime candidate for use with XYO. Through studies and testing of specific models, XYO balancers can be custom designed for implementation in virtually any compressor type.

XYO Balancers can be built inside the reciprocating compressors, on the crankshaft. This solution would greatly reduce noise & vibration, resulting in quiet, low vibration, ultra energy efficient Compressors. XYO can significantly reduce vibration for increased efficiency and less mechanical wear and tear.

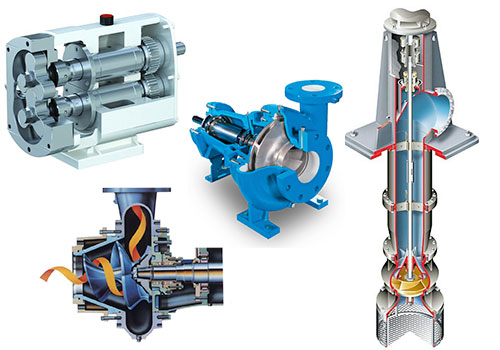

Impact of XYO on Pumps

- Reduced vibration

- Increased energy efficiency

- Minimized mechanical wear

- Lower maintenance costs

- Reduced downtimes

XYO Can be built into the Impeller and Electric Motor Armature

Pumps are a prime candidate for use with XYO. Through study and testing of specific models, XYO balancers can be custom designed for implementation in virtually any pump.

Manufactures have to balance the impeller and electric motor armature to minimize vibration in pumps. Pumps can go out of balance due to erosion, cavitation and deposit buildup on blades which leads to higher maintenance, repair and replacement costs.

XYO can be built into the electric armature of the pump motor, and into the pump impeller hub. This would resolve much of the vibration, resulting in a low vibration, high performance, energy efficient Pump.

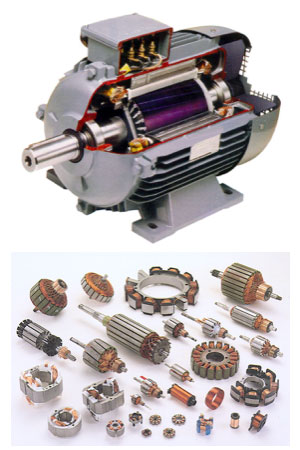

Impact of XYO on Electric Motors

- Energy usage decreased by 20%

- Reduced vibration

- Improved power output

- Lower manufacturing costs by eliminating conventional balancing methods

- Motor remains balanced during use, despite any dirt or debris build-up on armature

- Reduced maintenance costs

- Less downtime for repairs & rebalancing

XYO Balancer Built into the Armature of the Motor

In an industry focused on energy efficiency, XYO can produce extremely high performance, energy efficient parts and components for power systems. XYO has been successfully implemented on an electric motor. A prototype XYO balancer running on an unbalanced motor reduced vibration levels up to 45% and power consumption up to 19% compared to a factory balanced motor.

The results show that electric motors do not have to be balanced using conventional methods if they are running with the XYO technology.

XYO balancing technology is able to automatically & continuously compensate for variable mass imbalances. Electric motors equipped with XYO will be able to compensate for naturally occurring mass imbalances from manufacturing processes, and the those generated during operation.

XYO has substantial potential in this market and can impact both manufacturers and consumers by reducing the time and effort to balance motors using conventional methods while providing a better performing product with reliability and energy efficiency.

Engineering Reports and Technical Data

Please visit our technical website for more about XYO at: www.xyobalancer.com

Incubator of Innovative, Energy Efficient,

& Environmentally Friendly Technologies